In the food packaging industry, precision isn’t just about aesthetics—it’s a fundamental requirement for consumer safety and regulatory compliance. The quality of die cutting directly impacts packaging integrity, contamination risks, and ultimately, the safety of food products reaching consumers. Understanding why precision matters reveals the critical role advanced die technology plays in protecting public health.

Seal Integrity: The First Line of Defense

Packaging seals represent the primary barrier between food products and environmental contaminants. Imprecise die cutting creates irregular edges that compromise seal quality, leading to microscopic gaps where bacteria, moisture, and oxygen can penetrate.

Precision Cutting Impact on Seals:

- Clean, uniform edges enabling complete seal formation

- Consistent material thickness at seal points

- Elimination of rough edges that create seal weaknesses

- Perfect alignment for multi-layer packaging structures

- Reduced seal failure rates preventing contamination

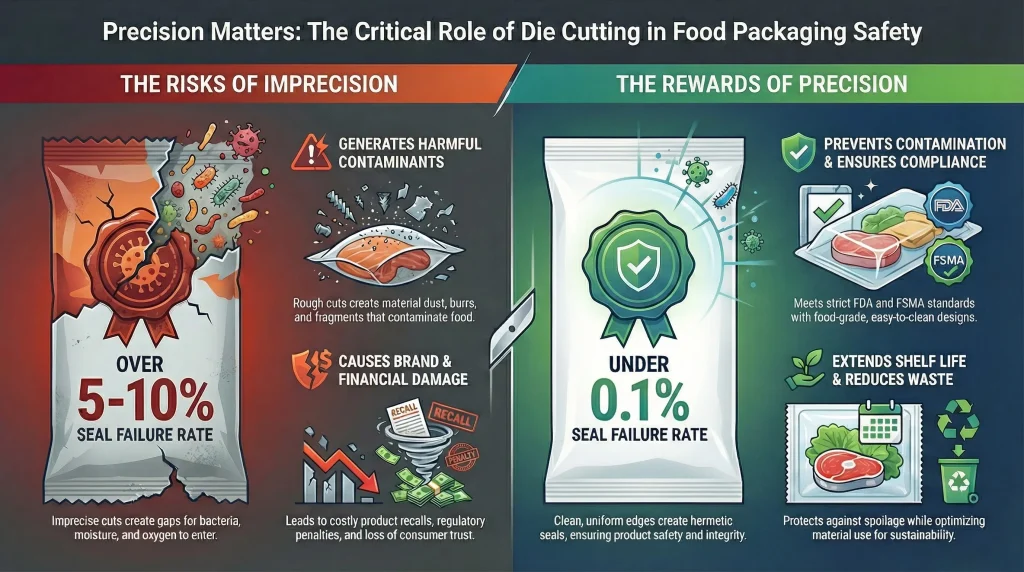

Poor die precision results in seal failure rates exceeding 5-10%, exposing food products to contamination and spoilage. Precision cutting reduces failures to less than 0.1%—a critical difference for food safety.

Contamination Prevention Through Material Control

Die cutting quality directly affects contamination risks during the packaging process. Imprecise cuts generate material particles, debris, and dust that can contaminate food products.

Precision die cutting minimizes contamination through:

- Burr-free edges eliminating particle generation

- Clean cuts reducing material tearing and fragmentation

- Controlled cutting pressure preventing material crushing

- Smooth operations minimizing vibration-induced debris

- Consistent quality reducing reject rates and material handling

For ready-to-eat foods and sterile packaging applications, this contamination control becomes absolutely critical for regulatory compliance.

Regulatory Compliance and Food Safety Standards

FDA regulations and FSMA (Food Safety Modernization Act) requirements demand rigorous contamination prevention throughout packaging production. Precision die cutting supports compliance through:

Compliance Advantages:

- Food-grade material compatibility with stainless steel construction

- Smooth surface finishes preventing bacterial growth

- Easy-to-clean designs meeting sanitation protocols

- Traceable manufacturing processes supporting documentation requirements

- Consistent quality output simplifying batch release procedures

Regulatory audits increasingly scrutinize packaging equipment as potential contamination sources. Precision dies with proper materials and construction meet these stringent requirements.

Shelf Life Extension Through Package Integrity

Precise packaging seals directly impact product shelf life by controlling oxygen transmission, moisture migration, and microbial access. Even microscopic seal imperfections can reduce shelf life by 30-50%.

High-precision die cutting ensures:

- Hermetic seals for oxygen-sensitive products

- Moisture barriers protecting dry goods

- Tamper-evidence through consistent seal patterns

- Gas barrier integrity for modified atmosphere packaging

- Extended freshness reducing food waste

Material Efficiency and Sustainability

Precision cutting optimizes material utilization, reducing waste while maintaining packaging integrity:

- Tighter nesting patterns maximizing material yield

- Reduced scrap generation lowering disposal costs

- Minimal rework requirements from first-time accuracy

- Sustainable practices through waste reduction

- Cost efficiency improving profitability margins

For companies with sustainability commitments, precision die cutting aligns environmental goals with operational efficiency.

Speed Without Compromising Safety

Modern food production demands high-speed packaging to meet market demands. Precision rotary dies enable rapid production while maintaining the quality standards essential for food safety:

Production Benefits:

- Continuous operation at 500-1500 cuts per minute

- Consistent quality throughout production runs

- Automated processes reducing human handling

- Predictable maintenance preventing unexpected downtime

- Scalable production meeting demand fluctuations

Specialized Applications Requiring Precision

Certain food packaging applications demand exceptional precision:

Modified Atmosphere Packaging (MAP): Requires perfect seals maintaining specific gas compositions

Aseptic Packaging: Demands contamination-free production for sterile products

Portion Control: Needs exact cutting for consistent serving sizes

Child-Resistant Packaging: Requires precise features meeting safety standards

The Technology Investment That Protects Everything

While high-precision food-grade dies require greater initial investment, the risk mitigation they provide far exceeds cost considerations. The potential losses from contamination incidents, recalls, or regulatory violations dwarf equipment investments.

Quality die technology delivers:

- Food safety assurance protecting consumers

- Regulatory compliance avoiding penalties

- Brand protection maintaining reputation

- Operational efficiency through reliable performance

- Long-term cost savings from reduced failures

Protect your brand and consumers with precision die cutting designed specifically for food packaging safety. Sakazaki’s food-grade die solutions combine advanced precision engineering with food-safe materials and construction, ensuring your packaging meets the highest safety and quality standards.