- Celebrating 100 Years!

Leading Solid Rotary Die Manufacturer in India

At Sakazaki, we’re committed to precision, innovation, and excellence in crafting high-quality solid rotary die cutters for various industries.

5000+ Happy Customers Worldwide

- Japanese Rotary Die Maker

Pioneering in Solid Rotary Die Cutting Production

We specialize in manufacturing high-quality solid rotary die cutters that empower industries worldwide, with decades of experience and a commitment to innovation.

- What we do?

Our Services

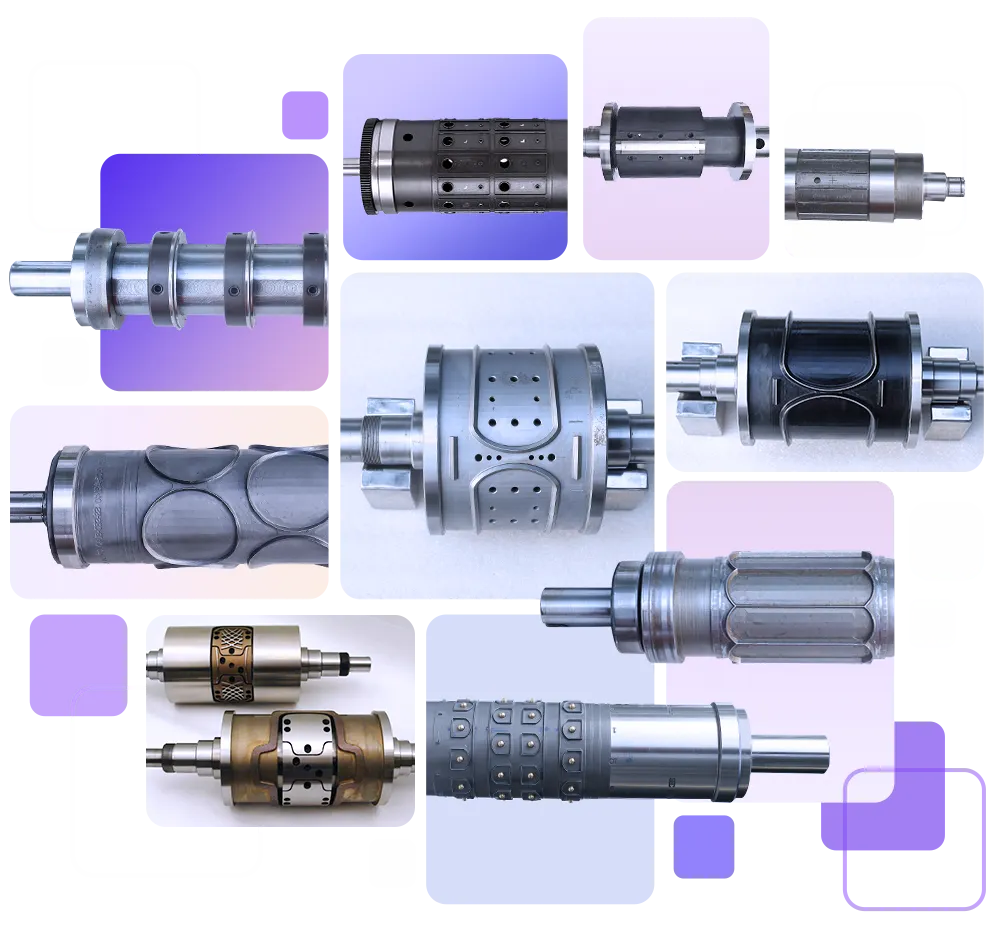

Our expertise lies in intricately crafting custom solid rotary and flat die cutters precisely adapted to diverse industrial demands, guaranteeing peak operational performance.

Die Manufacturing

With an emphasis on accuracy, We stand out in fabricating rotary and flat dies tailored to diverse industry needs, guaranteeing top-notch performance and productivity.

Die Maintenance

Dedicated to precision and reliability, we offer tailored maintenance solutions for rotary and flat die cutters, ensuring prolonged functionality and peak performance.

Die Rebuilding

We specialize in comprehensive rebuilding services for rotary and flat die cutters, restoring them to optimal functionality for continued performance.

Reverse Engineering

Utilizing our mastery in reverse engineering, we excel in reconstructing various components, ensuring precise replication and improved functionality.

- Our Workflow

Crafting Dies with Seamless Collaboration

Explore our streamlined workflow crafted for efficiency. Discover how we prioritize tasks, collaborate seamlessly, and consistently deliver results that exceed expectations.

- Conceptualize and model the die using CAD.

- Simulate and prototype for validation.

- Choosing appropriate materials based on the application of die.

- Considering durability, heat resistance, and cost-effectiveness.

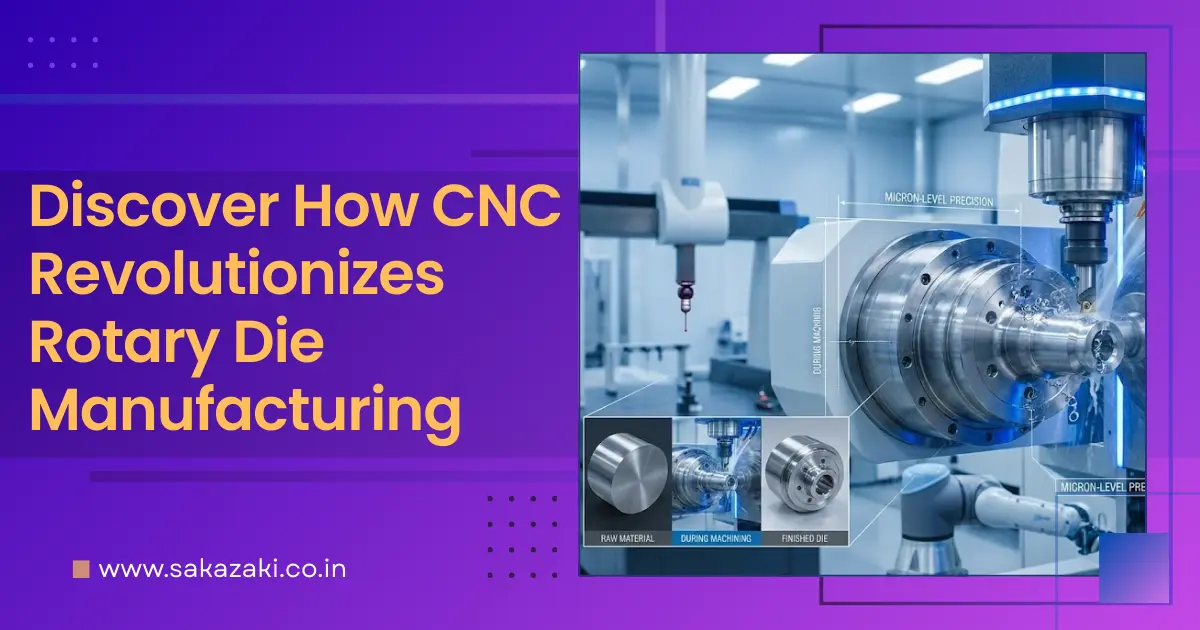

- Use CNC machines to precision-cut and forming patterns according to customer needs.

- Doing heat treatment processes and surface finishing techniques.

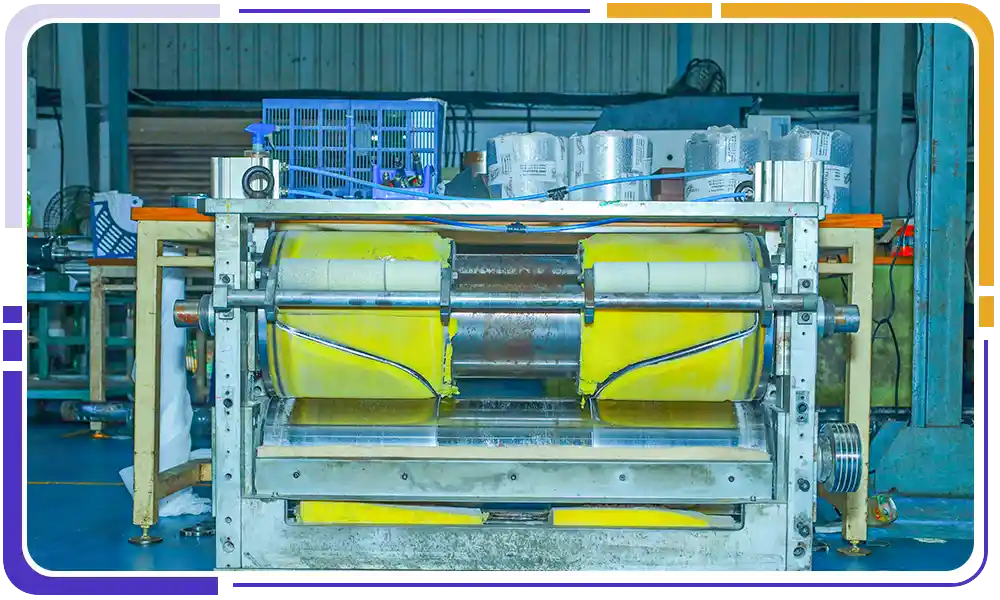

- Manufacture the frame unit and assemble other components with trouble-free fitting.

- Conduct rigorous quality checks and inspections.

- Perform tests to ensure the die meets design specifications.

- Check the die's dimensional accuracy and tolerance levels

- Our Expertise

Industries Empowered by Our Products

At Sakazaki, we focus on creating personalized solutions designed to meet the unique needs of various industries. Our solutions are aimed at efficiently improving their production processes.

Sakazaki presents premium solid rotary die cutters, elevating the production of hygiene essentials with unparalleled excellence.

Sakazaki provides top-tier solid rotary die cutters, optimizing the fabrication of medical necessities such as bandages, masks, etc.

We provide deluxe solid rotary die cutters, refining the production of labelling and packaging items, like wrappers, tags, and beyond.

Sakazaki offers top-notch solid rotary die cutters, improving the manufacturing of electronic goods like gaskets, adhesives, etc.

Sakazaki provides top-of-the-line solid rotary die cutters, elevating the production of food items with precision and efficiency.

- Our Specialties

Why Choose us?

Experience superior service quality driven by our expertise, reliability, and commitment to exceeding expectations. Choose us for a seamless journey towards your goals.

We adhere strictly to stringent quality control measures, ensuring our Flat dies and Die Cut Rollers meet the highest standards of performance and reliability.

At Sakazaki, We prioritize client satisfaction through transparent communication, timely delivery, and ethical business practices, fostering long-term partnerships.

With a skilled team boasting extensive industry knowledge, we consistently innovate and adapt, delivering tailored solutions to meet diverse client needs.

Our utilization of advanced machinery and cutting-edge technology ensures precision engineering, delivering products that surpass industry expectations.

Feel free to consult with our experts!

- Testimonial

What do our Customers say about us?

Explore experiences shared by our clients. Dive into their feedback for a glimpse into our service quality.

” Our manufacturing improved a lot with these top-quality dies. I highly recommend Sakazaki for its great performance and long-lasting products.”

Industrial Manager

” These dies are durable and efficient, significantly enhancing our manufacturing. Highly recommended for anyone seeking reliable performance and quality products.”

Managing Director

” We’re impressed by the durability and performance of these dies. They’ve significantly enhanced our operations, making them more efficient and reliable .”

Product Manager

- FAQs

Your questions answered.

Discover helpful answers to common inquiries in our resource section. Find solutions to your queries effortlessly.

1. Can you offer the Re-grinding service for my existing Dies?

Absolutely! Our expert re-grinding service revitalizes your existing dies, enhancing precision and performance, ensuring prolonged usability and cost-effectiveness for your manufacturing operations.

2. What is the typical project duration for a die manufacturing?

Project durations vary based on complexity but typically range from weeks to a few months, accounting for design, fabrication, and testing phases.

3. What materials are suitable for Rotary Dies?

Rotary dies can be crafted from various materials like steel, carbide, and titanium, chosen based on specific application requirements for durability and precision.

4. What after-sales support and services do you provide?

We offer comprehensive after-sales support, including training, troubleshooting, and spare parts availability, ensuring uninterrupted production and maximum uptime for our clients.

5. How can we extend the lifespan of a rotary die?

Standard upkeep, lubrication, and periodic inspections are essential for optimal performance and longevity, supported by our maintenance guidelines and technical expertise.

- Get yourself updated