- What we do?

Die Rebuilding

Elevate your production capabilities with our specialized die rebuilding services. We restore precision and extend operational life.

- Rejuvenate your Dies

Maximizing Longevity And Efficiency

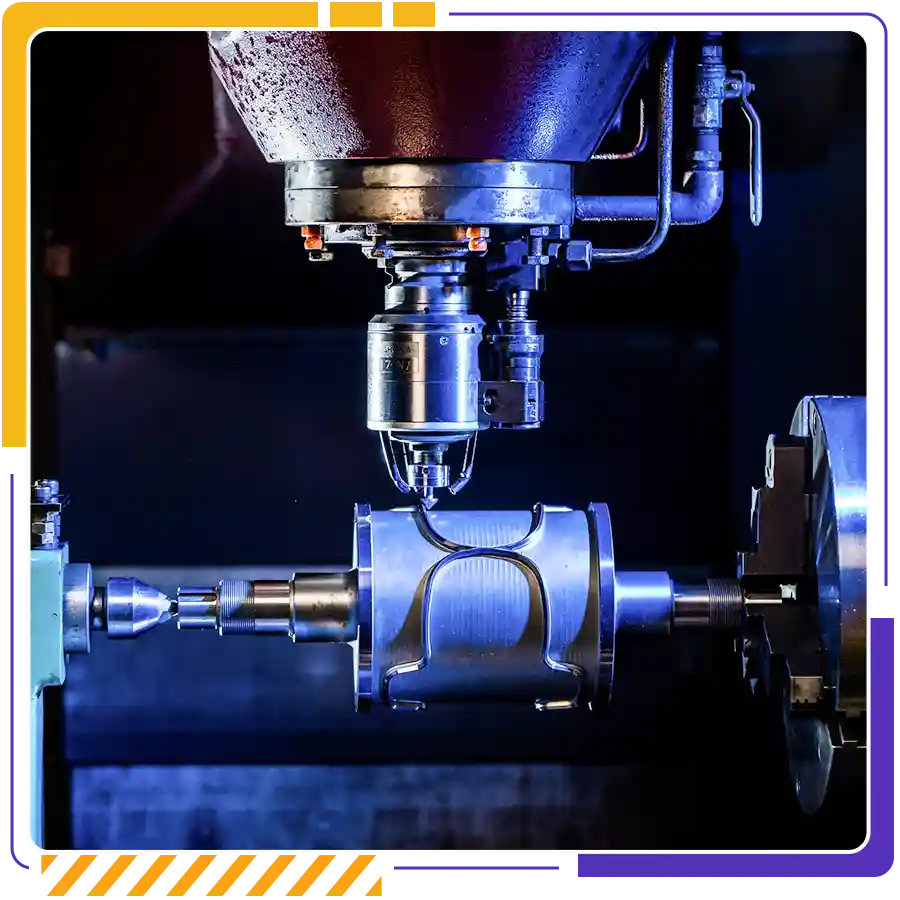

Die Rebuilding is the process of complete service of Frame unit. The possibility of cylinder deflection or misalignment can also be an important factor, as can anvil roller diameters, cylinders losing traction, sturdiness of the side frames, and friction in the cutting unit creating too much heat.

In Die rebuilding service, we monitor the following parts and ensure their working conditions.

- Side Frame

- Bearing Block

- Pressure Bridge

- Magnetic Cylinder or Rotary Die

- Anvil Roller

- Support Roller

- Die Revitalization

Process involved in

Die Rebuilding Service

The existing dies to identify wear, damage, or areas needing improvement.

Documenting dismantled Die Components condition and noting any areas requiring repair or replacement.

Remove contaminants, residue, and any damaged material from the die components

Address identified issues by welding, machining, or replacing damaged parts.

Utilize advanced machining techniques to ensure dimensional accuracy, surface finish, and proper alignment.

Perform quality checks, and conduct rigorous testing to ensure the rebuilt die meets performance standards.

- Uncover Benefits

Dies Renewed, Enhanced.

Our comprehensive process, from assessment to precision refurbishment, guarantees extended durability and peak performance for your dies.

Restoring dies through rebuilding enhances functionality and durability, prolonging their usability while minimizing costs and resource consumption.

- Extends The Life of Your Dies

- Ensures Proper Functionality

- Meets OEM Specifications

- Excellent Performance

- Negligible Maintenance

- Smooth Operation

- Testimonial

What do our Customers say about us?

Explore experiences shared by our clients. Dive into their feedback for a glimpse into our service quality.

” Our manufacturing improved a lot with these top-quality dies. I highly recommend Sakazaki for its great performance and long-lasting products.”

Industrial Manager

” These dies are durable and efficient, significantly enhancing our manufacturing. Highly recommended for anyone seeking reliable performance and quality products.”

Managing Director

” We’re impressed by the durability and performance of these dies. They’ve significantly enhanced our operations, making them more efficient and reliable .”

Product Manager

- Get yourself updated