Why Is Precision Die Cutting Essential for Food Packaging Safety and Quality?

In the food packaging industry, precision isn’t just about aesthetics—it’s a fundamental requirement for consumer safety and regulatory compliance. The quality of die cutting directly impacts packaging integrity, contamination risks, and ultimately, the safety of food products reaching consumers. Understanding why precision matters reveals the critical role advanced die technology plays in protecting public health. […]

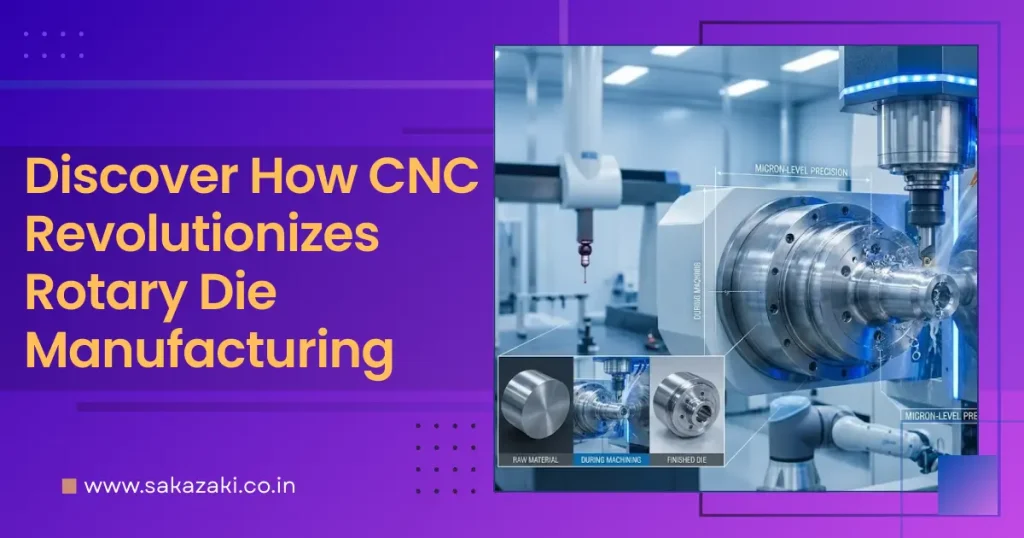

How Does CNC Technology Improve Die Manufacturing Precision?

The evolution from manual machining to Computer Numerical Control (CNC) technology represents one of the most transformative advances in die manufacturing history. This technological leap doesn’t just improve precision—it fundamentally redefines what’s possible in creating rotary and flat dies that meet today’s exacting manufacturing standards. Precision Beyond Human Capability Traditional manual machining, regardless of […]

How Does Die Rebuilding Compare to Buying New Dies?

When a rotary die shows signs of wear, manufacturers face a critical decision: invest in a brand-new replacement or rebuild the existing die? This choice significantly impacts both operational budgets and production timelines. Understanding the true comparison between these options can save your company substantial resources while maintaining peak manufacturing performance. The Cost […]

Why Sakazaki Rotary Dies Outperform Standard Industry Dies: A Technical Comparison

In the precision die-cutting industry, not all rotary dies are created equal. While many manufacturers claim quality, the technical specifications tell a dramatically different story. When you compare Sakazaki rotary dies to industry-standard alternatives, the performance gap becomes impossible to ignore. Precision That Redefines Standards The foundation of superior die performance starts with dimensional […]

How Can Professional Die Maintenance Extend Equipment Lifespan?

Rotary dies represent significant capital investments for manufacturing operations. Yet many companies unknowingly accelerate wear and reduce performance by neglecting proper maintenance protocols. The difference between a die lasting 18 months versus 5+ years often comes down to one critical factor: professional maintenance. True Cost of Neglected Maintenance When rotary dies don’t receive proper […]

What Makes Rotary Biscuit Dies Superior to Traditional Cutting Methods?

In the competitive world of biscuit manufacturing, production efficiency and product consistency can make or break a bakery’s success. While traditional reciprocating cutters have served the industry for decades, rotary biscuit dies are rapidly becoming the preferred choice for manufacturers who demand higher output, better quality, and lower operational costs. The Speed Revolution in […]

How Are Rotary Dies Revolutionizing Medical Device Manufacturing?

The medical device industry operates under the most stringent quality and safety standards in the manufacturing sector. As regulatory requirements tighten and demand for precision medical components escalates, rotary die technology has emerged as the game-changing solution that’s reshaping how medical devices are produced. Precision That Saves Lives In medical device manufacturing, microscopic variations […]

What Makes Japanese Die-Cutting Technology Superior to Traditional Methods?

When it comes to precision manufacturing, Japanese die-cutting technology stands alone in its class. The difference isn’t just about advanced machinery—it’s a fundamental philosophy that combines meticulous engineering, superior materials science, and centuries of craftsmanship into every cutting-edge product. The Philosophy of Perfection Japanese manufacturing adheres to the principle of “Monozukuri”—a profound commitment to […]

How Do Solid Rotary Dies Transform Modern Manufacturing Efficiency?

The Continuous Operation Advantage The manufacturing revolution is happening right now, and solid rotary dies are at the centre of this transformation. While traditional cutting methods struggle to meet modern production demands, solid rotary technology is rewriting the rules of industrial efficiency and setting new benchmarks for productivity across multiple industries. Unlike conventional cutting systems […]

What Are the Key Differences Between Flat Dies and Rotary Dies?

Flat Dies and Rotary Dies When selecting the right die-cutting solution for your manufacturing process, understanding the fundamental differences between flat dies and rotary dies reveals why modern industries are rapidly shifting toward rotary technology. While both methods serve cutting purposes, the efficiency gap between them is becoming increasingly significant. Flat Dies: The Traditional […]