The evolution from manual machining to Computer Numerical Control (CNC) technology represents one of the most transformative advances in die manufacturing history. This technological leap doesn’t just improve precision—it fundamentally redefines what’s possible in creating rotary and flat dies that meet today’s exacting manufacturing standards.

Precision Beyond Human Capability

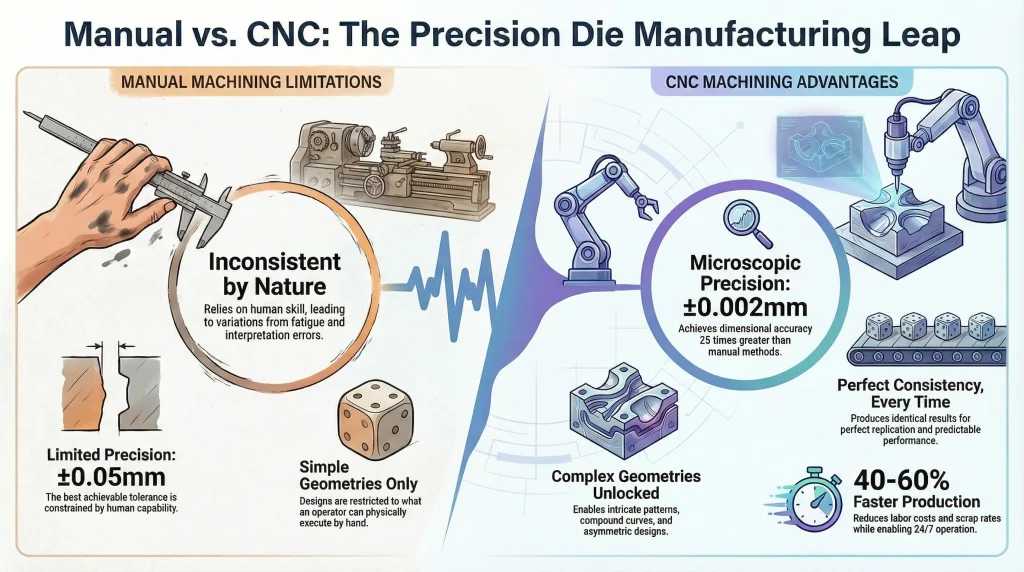

Traditional manual machining, regardless of operator skill, is inherently limited by human factors. Hand-eye coordination, fatigue, and measurement interpretation all introduce variables that compromise consistency.

CNC technology eliminates these variables. Programmed cutting paths execute with mechanical precision measured in microns, achieving tolerances that were previously impossible:

Precision Achievements:

- ±0.002mm dimensional accuracy vs ±0.05mm manual tolerance

- Repeatable positioning within 0.001mm across millions of operations

- Consistent depth control, eliminating variation between cuts

- Perfect angular accuracy for complex geometries

- Uniform surface finishes across the entire die surfaces

This level of precision is critical for industries such as medical devices, electronics, and aerospace, where microscopic variations can cause product failures or safety concerns.

Complex Geometries Made Possible

Manuals die manufacturing limits to what human operators can physically execute. CNC technology removes these constraints, enabling intricate patterns and sophisticated geometries that enhance die performance.

Multi-axis CNC machines can create:

- Intricate cutting patterns with varying depths and angles

- Compound curves are impossible to achieve manually

- Precise perforation patterns with uniform spacing

- Embossed designs with consistent relief depths

- Asymmetric geometries optimized for material flow

These advanced capabilities allow engineers to design dies that maximize cutting efficiency while minimizing material waste—optimizations impossible with traditional manufacturing methods.

Consistency Across Production Runs

The most significant CNC advantage lies in absolute consistency. Once a die design is programmed, CNC machines produce identical results regardless of production volume.

Consistency Benefits:

- Perfect replication when manufacturing replacement dies

- Zero variation between dies in matched sets

- Predictable performance across the entire die inventory

- Simplified quality control with standardized outputs

- Reliable spare parts matching original specifications exactly

For manufacturers operating multiple production lines or requiring matched die sets, this consistency becomes invaluable for maintaining uniform product quality.

Reduced Production Time and Costs

While CNC equipment represents a significant capital investment, the operational efficiencies deliver compelling economic returns. Automated machining operates continuously with minimal supervision, dramatically reducing labour costs while accelerating production timelines.

Time and Cost Advantages:

- 24/7 operation capability without fatigue-related errors

- Reduced setup times for complex manufacturing operations

- Faster production cycles through optimized tool paths

- Lower scrap rates from first-time accuracy

- Reduced rework requirements, eliminating costly corrections

CNC manufacturing typically reduces die production time by 40-60% compared to manual methods while improving quality outcomes.

Design Flexibility and Rapid Prototyping

CAD/CAM integration with CNC technology revolutionizes the design-to-production workflow. Engineers can:

- Simulate cutting operations before physical production

- Optimize tool paths for efficiency and surface quality

- Test design variations quickly and cost-effectively

- Modify designs rapidly based on testing results

- Produce prototypes in days rather than weeks

This flexibility accelerates product development cycles, enabling die manufacturers to respond quickly to market demands or customer specifications.

Material Optimization and Waste Reduction

CNC precision extends to material utilization. Programmed cutting paths maximize material efficiency while maintaining structural integrity:

- Optimized material removal, preserving die strength

- Minimal waste generation through precise cutting

- Strategic material placement where performance demands

- Reduced material costs through efficient utilization

- Environmental benefits from waste minimization

Quality Assurance Integration

Modern CNC systems incorporate real-time quality monitoring, detecting deviations instantly:

Quality Control Features:

- In-process measurement verifying dimensions during production

- Automatic tool wear compensation maintains accuracy

- Statistical process control tracking performance trends

- Digital documentation supporting quality certifications

- Traceability systems meeting regulatory requirements

Future-Ready Manufacturing

CNC technology positions die manufacturers for Industry 4.0 integration:

- IoT connectivity enabling remote monitoring

- Predictive maintenance prevents unexpected downtime

- Data analytics optimizing production efficiency

- Automated workflow integrating design through delivery

- Digital twin technology simulating production scenarios

The Competitive Imperative

In today’s manufacturing landscape, CNC precision isn’t a luxury—it’s a competitive necessity. Companies demanding zero-defect quality, rapid turnaround, and complex geometries require CNC-manufactured dies to meet their production standards.

The technology gap between CNC and manual manufacturing continues widening as software capabilities advance and machine precision improves. Manufacturers partnering with CNC-equipped die makers gain decisive advantages in quality, speed, and design flexibility.

Experience the precision that only advanced CNC manufacturing delivers. Sakazaki’s state-of-the-art CNC facilities combine cutting-edge technology with century-old craftsmanship expertise, producing dies that meet the most demanding specifications across multiple industries.