In high-speed, high-demand industries such as medical devices, hygiene products, and electronics, moving from concept to production quickly—without sacrificing quality—is a decisive competitive advantage. At the heart of this fast-paced innovation lies a critical tool: the custom rotary die.

Custom rotary shaping materials shape the future of product development. Companies like Sakazaki ensure this transition from design to delivery is seamless, efficient, and precise.

What Are Custom Rotary Dies?

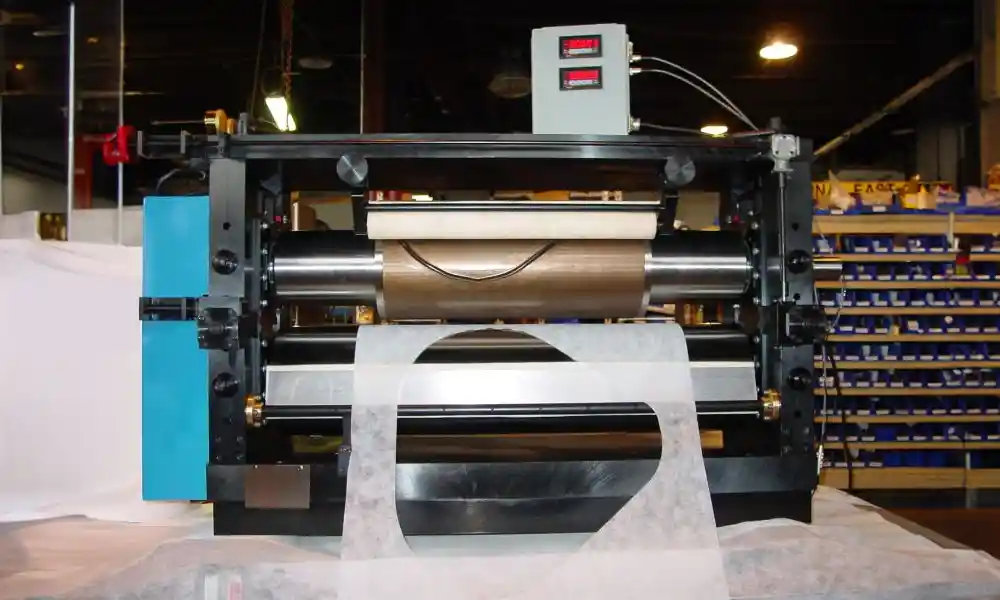

Custom rotary dies are cylindrical tools designed to cut, perforate precisely, and form materials during roll-to-roll (web) manufacturing. Unlike off-the-shelf tools, these dies are tailored to meet unique product specifications, materials, tolerances, and application challenges.

Whether a multi-layered medical sensor or a high-speed packaging solution, custom dies allow manufacturers to translate their design blueprints into high-performance, manufacturable products rapidly.

How Custom Rotary Dies Accelerate Product Development

1. Rapid Prototyping to Production Scale

Custom dies enable the quick iteration of prototypes while maintaining the scalability to move directly into mass production without redesigning tooling.

Sakazaki supports customers with design consultation and quick-turn prototyping, minimizing time-to-market without compromising accuracy.

2. Enhanced Tolerance Control

In industries where microns matter, precision is non-negotiable. Custom dies ensure accurate depth, alignment, and geometry based on material properties and application needs.

With micron-level cutting precision, Sakazaki’s dies deliver flawless cuts on even the most delicate or layered substrates.

3. Optimized for Material & Application

Each material behaves differently, be it foam, film, foil, adhesive, or biocompatible polymer. Custom dies are engineered for the specific material stack-up and end-use environment.

Sakazaki’s engineers evaluate every product’s use case to ensure perfect compatibility and long-term die durability.

4. Reduced Downtime & Rework

Well-designed custom dies lead to fewer errors, less waste, and longer tool life. That means reduced production downtime and consistent product output.

Sakazaki also offers die rebuilding and reverse engineering to optimize legacy designs or extend tool lifespan.

5. Faster Regulatory Compliance

It is key to quickly achieve design validation and production readiness in regulated industries like healthcare. Custom dies streamline this process by reducing variability and meeting tight tolerances from day one.

Sakazaki’s tooling systems are compliant with global manufacturing standards, including cleanroom and FDA-compliant environments.

Why Choose Sakazaki for Custom Rotary Dies?

With a legacy of precision, innovation, and quality, Sakazaki is a trusted partner in bringing custom designs to life. From single-cavity dies for prototyping to high-output production tools, Sakazaki empowers manufacturers to:

- The transition from idea to implementation is seamless.

- Optimize production efficiency and precision.

- Customize for unique materials and engineering challenges.

- Maintain long-term tooling performance with expert support.

Are you ready to bring your product design to life with precision tooling?

Contact Sakazaki today for custom rotary die solutions that reduce lead time and boost performance. Sakazaki doesn’t just build dies—it helps build better products.