Understanding Battery Gasket Cutting Dies

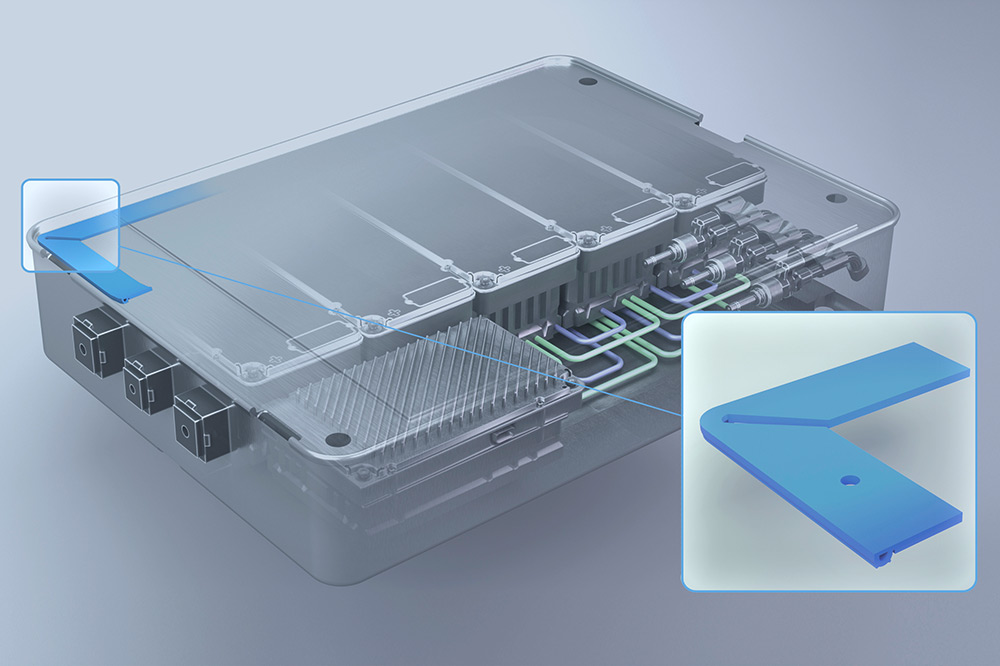

Battery gasket-cutting dies are specialized tools used in battery production. These die-shaped gasket materials are made into precise forms. The gasket acts as a seal, protecting the battery from leaks and contamination. Without this die, gasket production would be slow, inconsistent, and error-prone.

Why Battery Gaskets Are Critical

Gaskets are essential in preventing acid or electrolyte leakage. They also protect the battery’s internal structure from dust and moisture. Even slight damage to a gasket can reduce battery performance and lifespan. That’s why high-precision gasket dies are indispensable in modern manufacturing.

How the Cutting Die Works

A battery gasket cutting die slices gasket material using a customized mould. It applies pressure and cuts through the material accurately, ensuring a perfect fit every time. Whether rotary or flatbed, the die shapes the gasket within milliseconds. Automated systems then align and place the gaskets for further processing.

Materials Used in Battery Gasket Cutting

Manufacturers commonly use rubber, silicone, and plastic for battery gaskets. Each material requires a different die setup. The cutting die must match the gasket’s shape and tolerance exactly. High-speed steel or tungsten carbide is typically used to build these cutting tools.

Benefits of Precision Cutting Dies

Cutting dies offer speed, consistency, and accuracy. These tools lower human error, reduce waste and increase output. They also maintain uniformity in gasket size and thickness. This is crucial for large-scale battery manufacturers aiming for high efficiency.

Types of Gasket Cutting Dies

- Steel Rule Dies – Ideal for simple gasket shapes.

- Rotary Dies – Best for high-volume production

- Laser-Cut Dies – Suitable for intricate and small designs

- Custom Dies – Tailored for specific battery models.

Each type serves a different production need. The choice depends on the battery type, volume, and design requirements.

Role in Battery Performance

A well-cut gasket ensures proper sealing. It enhances battery durability and performance. Poorly cut gaskets lead to leakage, swelling, or battery failure. The cutting die’s precision directly impacts the battery’s reliability.

Industries That Rely on Battery Gasket Cutting Dies

- Automotive – For electric vehicle battery packs

- Electronics – In smartphones, tablets, and laptops

- Medical Devices – Powering compact and sterile devices

- Industrial Equipment – Ensuring long-lasting power sources

Each of these sectors requires custom gasket solutions. Cutting dies enables them to meet strict quality standards.

Challenges in Die Manufacturing

Design complexity and material tolerance are key challenges. The die must resist wear from repeated use. Maintenance and sharpening are also crucial. Even a minor defect in the die can lead to thousands of faulty gaskets.

Future Trends in Gasket Cutting Technology

Automation and laser-guided systems are growing trends. Smart dies integrated with sensors can monitor performance. These innovations help manufacturers detect issues before mass production. Sustainability and using eco-friendly gasket materials with recyclable dies are another focus.

Conclusion: The Backbone of Battery Production

Battery gasket-cutting dies may seem small, but they play a massive role. They are vital for ensuring safety and enhancing battery life. Investing in quality cutting dies guarantees superior battery performance and long-term reliability.

Would you like a visual diagram to show how the gasket-cutting process works?