What Is Die Rebuilding?

Die rebuilding is a process that restores worn or damaged dies to their original condition. It enhances performance, extends lifespan, and reduces costs. This service is essential for industries relying on precision tools.

Benefits of Die Rebuilding

Cost-Effective Solution

Replacing dies can be expensive. Rebuilding them helps save money while maintaining quality and efficiency.

Extended Tool Life

Die rebuilding restores functionality, extending the lifespan of tools and reducing the need for frequent replacements.

Improved Performance

Refurbished dies perform like new ones, ensuring precision and reliability in production.

Reduced Downtime

Minimizing breakdowns and failures leads to smoother operations and less disruption in manufacturing.

Die Rebuilding Process

Inspection and Assessment

Experts examine the die to assess wear and damage. They determine whether rebuilding is feasible.

Disassembly and Cleaning

The die is removed and cleaned thoroughly to remove debris, contaminants, and old coatings.

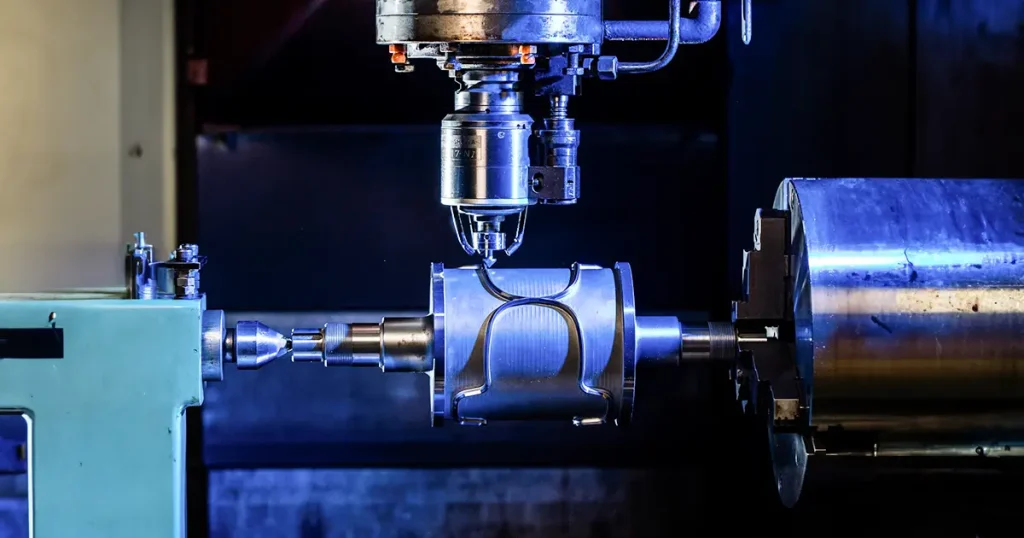

Repair and Reconditioning

Worn-out areas are repaired using welding, machining, or coating techniques to restore the die to optimal condition.

Final Testing and Quality Control

After rebuilding, the die undergoes rigorous testing to ensure precision, durability, and performance.

Industries That Benefit from Die Rebuilding

Automotive Industry

Die rebuilding helps maintain high precision in automotive manufacturing processes.

Metal Stamping

Restoring dies ensures consistency and accuracy in metal stamping operations.

Plastic Molding

Rebuilt dies to enhance the efficiency of plastic moulding, reducing waste and production errors.

Aerospace Manufacturing

Precision and reliability are critical in aerospace. Die rebuilding ensures high-quality production.

How to Choose a Reliable Die Rebuilding Service?

Experience and Expertise

Select a service provider with a strong track record and skilled professionals.

Advanced Technology

Ensure they use cutting-edge techniques and equipment for rebuilding.

Customer Reviews and Testimonials

Check feedback from previous clients to gauge service quality and reliability.

Comprehensive Service Package

Look for a provider that offers inspection, repair, and quality testing to guarantee top performance.

Conclusion

Die-rebuilding services help industries save money, improve efficiency, and extend the lifespan of essential tools. Choosing Sakazaki ensures optimal results, reducing downtime and enhancing productivity.